|

|

Post by tomqvaxy on Feb 14, 2021 5:02:21 GMT -5

|

|

|

|

Post by superflekmoonbird on Feb 14, 2021 10:23:16 GMT -5

That looks good.....

|

|

|

|

Post by 41chevy on Feb 14, 2021 11:22:14 GMT -5

This is K&S 1/16" Aluminum tubing. I put a piece of insulated automotive wire in it and slowly bent it over a Testers small bottle cap, the wire stops it from kinking. The aluminum tube can be polished to look like chrome or painted like this. Paul

|

|

|

|

Post by superflekmoonbird on Feb 15, 2021 20:08:51 GMT -5

I LIKE THAT TOO.

|

|

|

|

Post by Bernard Kron on Feb 15, 2021 20:44:19 GMT -5

Some super nice work going on with this project. Love the chassis detailing especially.

With respect to the rollover bar I've done a couple of projects that take advantage of a polished-aluminum-to-look-like chrome solution, one full width and one drivers side only.

This one is a '29 Roadster inspired by the 555 car with a full width hoop-style bar. The polished aluminum portion has pins on the ends that fit into tabs on the main frame structure so the model can be displayed with or without the body mounted. That's how I was able to do the "cutaway" photo:

The second one is a Deuce lakes-style roadster with the driver's side hoop style. The car has a full bellypan so it was built with no chassis detail and the hoop is mounted permanently to the bodywork:

I hope this gives you some ideas. Whatever you come up with I'm sure will look sharp as tack! |

|

|

|

Post by superflekmoonbird on Feb 15, 2021 21:12:41 GMT -5

Man that # 510 is nice !

Very much like where I'm going with this one.

Do you bend aluminum tubing with inserts to hold and not kink....and do you glue or solder tube to tube ?

|

|

|

|

Post by Bernard Kron on Feb 15, 2021 21:46:56 GMT -5

|

|

|

|

Post by superflekmoonbird on Feb 16, 2021 19:50:52 GMT -5

Thanks for the links, the more I look, the more there is to see and appreciate.

I'll be saving pictures of it for future reference.

|

|

|

|

Post by superflekmoonbird on Mar 5, 2021 17:03:50 GMT -5

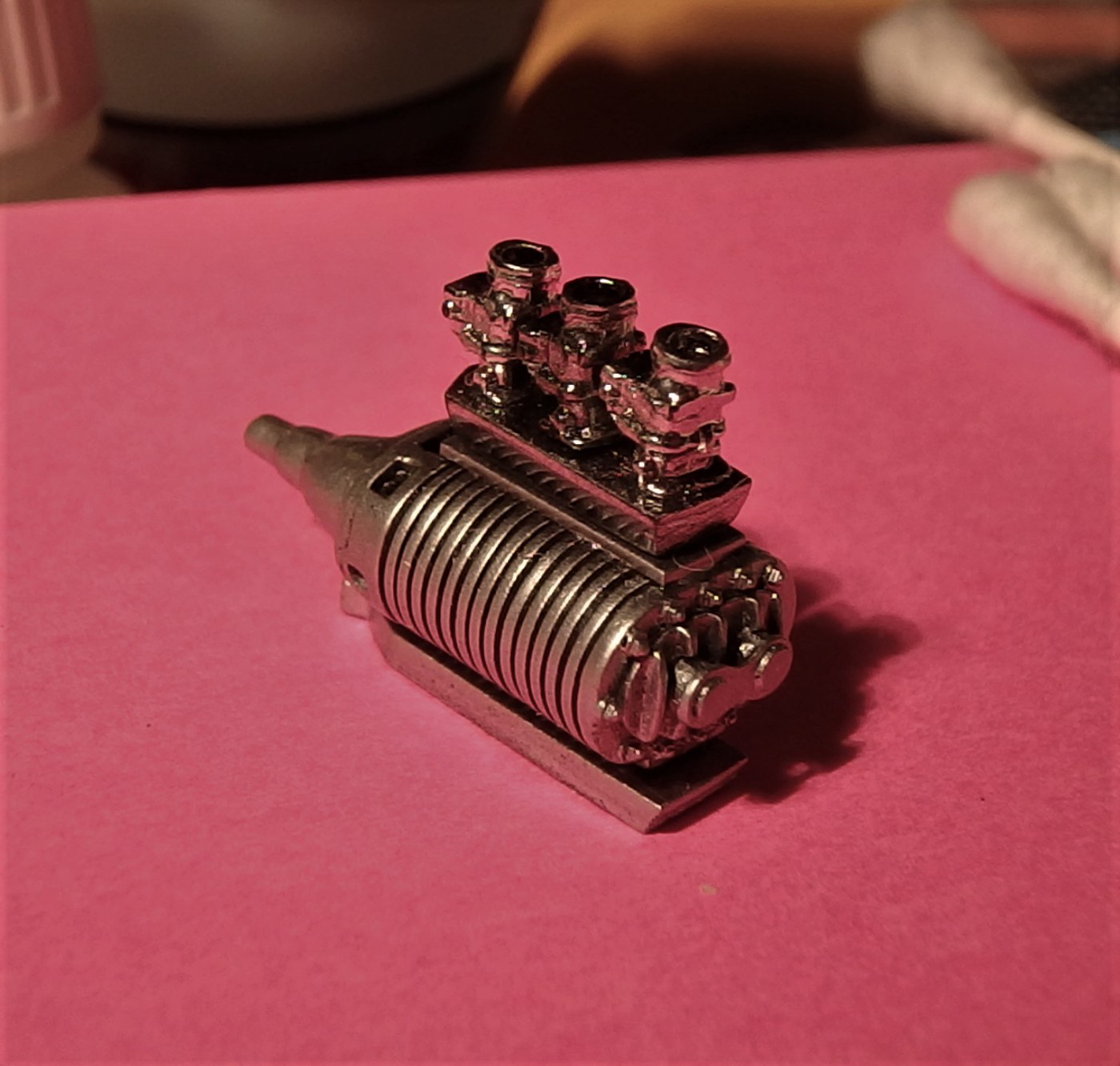

I shot some ALCLAD black base coat for the exhaust headers and flathead engine pulleys for this one. Decided to use the scratch built Italmechanica blower so I shot that in black too. Will wait for that to dry then try some Aluminum ALCLAD on that. Interior body panels got the black base coat as well. Put suspension parts and wheels in white primer, so hopefully I'll get this one moving along.  |

|

|

|

Post by 41chevy on Mar 5, 2021 21:54:16 GMT -5

That blower look good. If you wanted more shiny metal, quite a few of the distributor drive cover (only the round unit) between the water pumps were cast in aluminum for commercial apps. Saved a few pounds and allowed more static timing for blown flatties. Paul

|

|

|

|

Post by superflekmoonbird on Mar 6, 2021 20:17:23 GMT -5

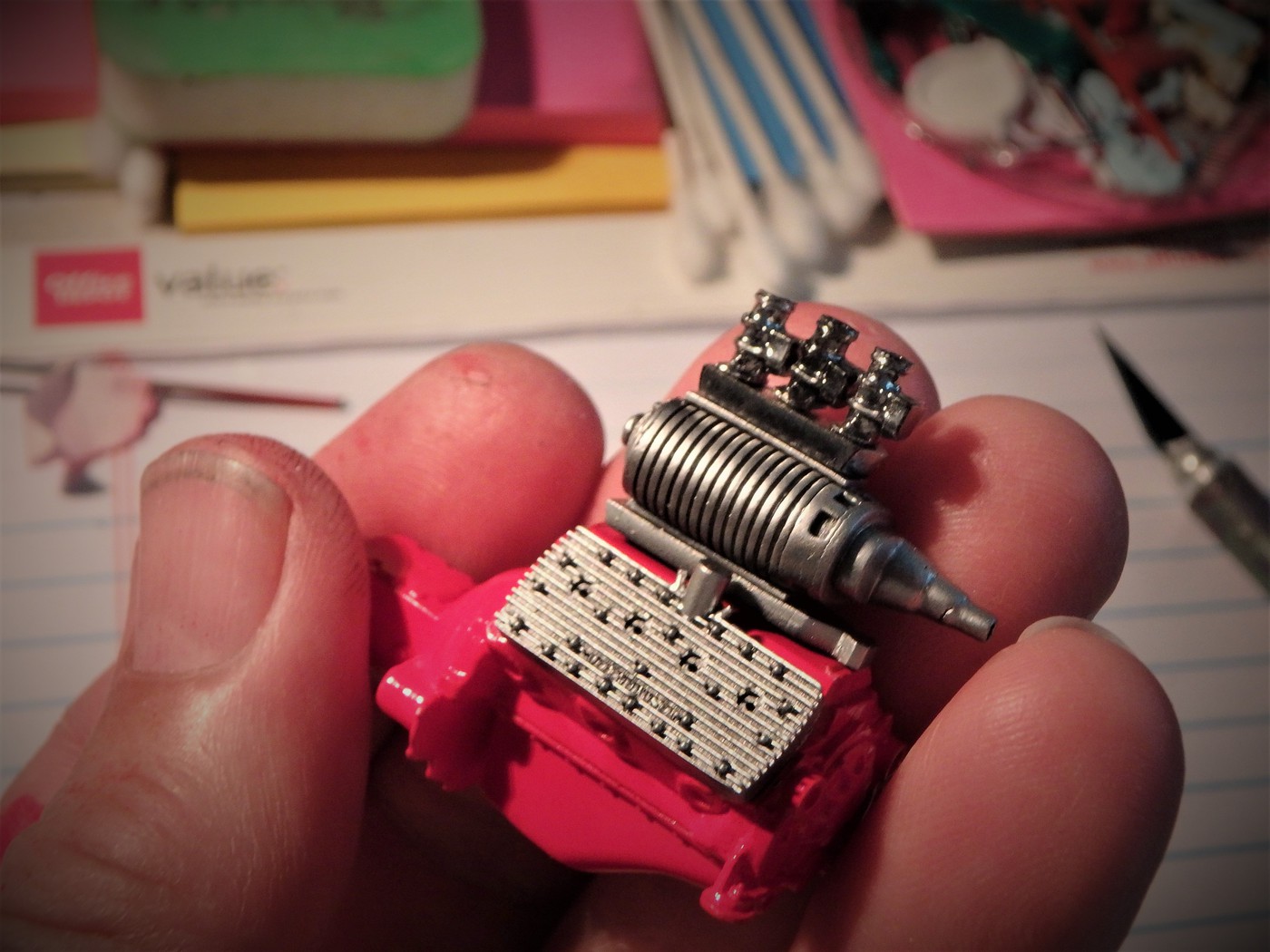

Applied ALCLAD aluminum on blower, chrome on Stromberg 97 carbs.   |

|

|

|

Post by Mr. Metallic on Mar 8, 2021 7:31:39 GMT -5

I guess I missed the fact that you scratchbuilt that SCoT blower. Beautiful work

|

|

|

|

Post by superflekmoonbird on Mar 8, 2021 14:00:32 GMT -5

...Thanks...built it before Norm at R & M came out with his more accurate and nicer SCOT blower. Been debating what to do with this...since I got Norm's nicer piece now. This one has an older look to it to me...maybe it would look better on an older vintage lakester.... Having trouble fitting the center water hose port resin flathead valve covers with this blower...I started this project with valve covers with front ports, which I manhandled trial fitting and chipped fins off the corner of the valve covers. So I painted these replacements...but now the blower won't center up now....with the ports being in the center rather than in front. Just goes to show ya.... IT'S ALWAYS SOMETHING. ![]()  |

|

|

|

Post by cturner on Mar 8, 2021 18:59:52 GMT -5

ehhh...get a set of front water connections from Norm and finish it like that...SWEET looking motorvator my friend!

|

|

|

|

Post by Mr. Metallic on Mar 9, 2021 6:55:31 GMT -5

I think there's a set of finned front port heads in the AMT 41 Woody. May even be branded?

|

|