|

|

Post by spex84 on Dec 4, 2014 2:26:08 GMT -5

Thanks for the tip, Randy...I'll have to do a comparison test some time. I tend to use 5 minute epoxy. ... Have not been finding much time for building lately, but the other night I started figuring out how to route the spaghetti on the front of this mill. The DeSoto Firedome in the '53 F-100 kit has an upper radiator hose that splits into 2 outlets, but no lower hose. I spent a while peering at too-small reference images and ended up building something that I think is more representative of what a 1:1 solution would look like. The upper hose needs its angle/length tweaked still, but it's just about there. I discovered after building the bungs on the intake for the twin water lines (black wires in photo) that they were hitting the valley cover, so I scratchbuilt a new valley cover too. I'll show that later. It's pretty basic, and thinner than the finned/chromed kit piece, which is too flashy anyways. Also, the frame now sports body locator tabs (should have done this a LONG time ago) and some friction shocks (because tube shock stanchions would clutter up the view).  ![]() |

|

|

|

Post by randfink on Dec 4, 2014 10:56:25 GMT -5

DANG, this is sweet! I'm diggin' all the extra realism you're building into this.

|

|

|

|

Post by Dennis on Dec 4, 2014 15:30:19 GMT -5

Nice! Building coolant hoses can be a pain in the ass, especially in situations like this with log manifolds and you have to figure out how to get the water out of both heads and up to the radiator. That's what I like about Chrysler hemi's with the factory tube across the front of the heads so log intakes don't complicate things.

|

|

|

|

Post by spex84 on Dec 4, 2014 17:29:00 GMT -5

Yep...a lot of the reference images that kept popping up were Chrysler 392s with the stock water crossover and chevy big-block water pumps with a modified timing cover. Much, much simpler!

|

|

|

|

Post by dodgefever on Dec 5, 2014 5:25:14 GMT -5

Nice problem solving.  |

|

|

|

Post by Murphy on Dec 5, 2014 7:59:06 GMT -5

I've found solder to work well for forming coolant hoses (FWIW)

|

|

|

|

Post by spex84 on Dec 5, 2014 12:44:17 GMT -5

Thanks for the tip John! I've used solder before; I was trying to use plastic in this case because it's easier to drill and pin together with regular glue or Ambroid.

If I had to do this again, I think I'd use solder for the upper and lower hoses.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Dec 7, 2014 20:03:34 GMT -5

Amazing work!

|

|

|

|

Post by constructionbob on Jun 4, 2015 15:09:22 GMT -5

I really dig this one. Hope U can find time and inspiration soon!

|

|

|

|

Post by spex84 on Jun 4, 2015 15:30:59 GMT -5

I'm just waiting for the humidity to drop here, then it's going back on the bench for some primer, final touchups and paint  I can't believe how much time has passed since I last worked on it. Thankfully, it's pretty much sorted by now. |

|

|

|

Post by bob29579 on Jun 18, 2015 19:59:12 GMT -5

Really looking good.

|

|

|

|

Post by spex84 on Sept 7, 2015 1:15:24 GMT -5

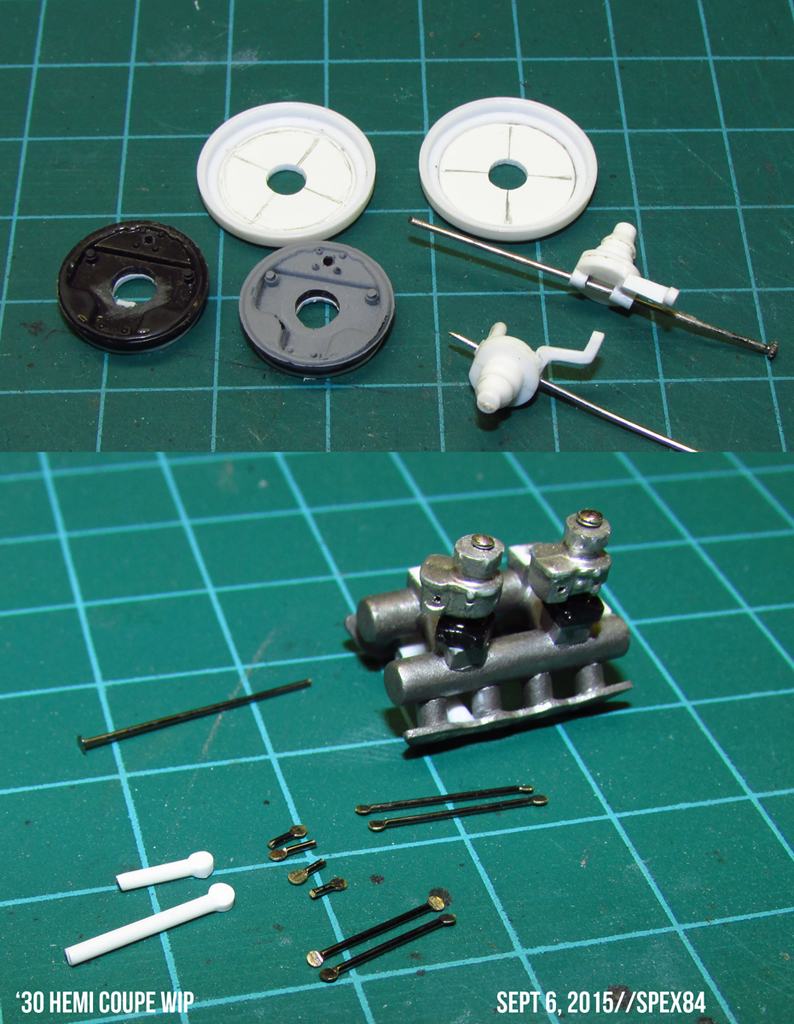

Whooaa....it's like a time warp over here. I look at the photos of this build and remember each stroke of the knife, but it was years ago now. Crazy. Anyway, today I got a coat of filler primer on the body (didn't want to, but realized the thinner primer I was using just wasn't cutting it). The wheels on one side have been painted bronze, and on the other side they'll be black. The block is bronze also. The body will be bare metal with a black frame and grill shell/hood. The idea is that on one side, I'll run the bronze wheels, caps, and open hood sides, and on the other...black wheels, no caps, and closed hood side. The idea is to represent a car that's being driven partially finished, and eventually the whole body will be black with bronze accents. I'm waiting to get the engine built and situated so I can figure out where to cut out the hood sides for valve cover clearance. The hood will also need holes for the air scoops, but I'll do that once the engine is solidly attached. I've done some paint tests for the bare metal effect, and I think it will involve grey primer, Future, "Mr Hobby" Steel, and maybe some graphite and rub 'n buff for variation. In the meantime, the various engine bits are getting painted, and I've been attempting to make some carb linkages out of wire...I was disappointed with my last attempt, so this time it's war. Gonna be fiddly though. The front brake backing plates were nested deep in the wheel backs, which made the front track width a little too narrow, so I made some plates to fill in the wheel backs and thickened the backing plate with some styrene sheet. Not sure if I posted since adding the steering arms to the spindles, but...yup, they're on there now.  |

|

|

|

Post by constructionbob on Sept 7, 2015 1:22:51 GMT -5

Cool. Nice U found this beast again!!!

|

|

|

|

Post by Johnny on Sept 7, 2015 2:23:58 GMT -5

Kool! I really dig the manifold/carb setup.

|

|

|

|

Post by spex84 on Sept 8, 2015 1:30:03 GMT -5

An exciting moment today...finally got a finish on the body! The process: -sanded primer fairly smooth -2 coats Future -drybrushed/stippled "Mr. Hobby Metal Color" Steel onto the body, trying to get an uneven but not blotchy finish. It ended up being very blotchy, much more so than my test pieces, perhaps because I used 2 coats of Future instead of 1, and the lack of "tooth" meant the paint wouldn't apply as evenly. So I continued dry-stippling the paint as it dried, which helped to even out the worst of the blotches. -after drying, I tried buffing with a cloth, which didn't help much. The finish was also too dark. -applied small amounts of Mr. Hobby Aluminum with a cloth, and rubbed it into the high spots/buffed with a cloth. This made the edges pop, and and actually knocked the blotches down to a more realistic level. So I'm pretty stoked with the result! The trick was to rub some half-dry paint into the surface and keep buffing as it dried.  |

|